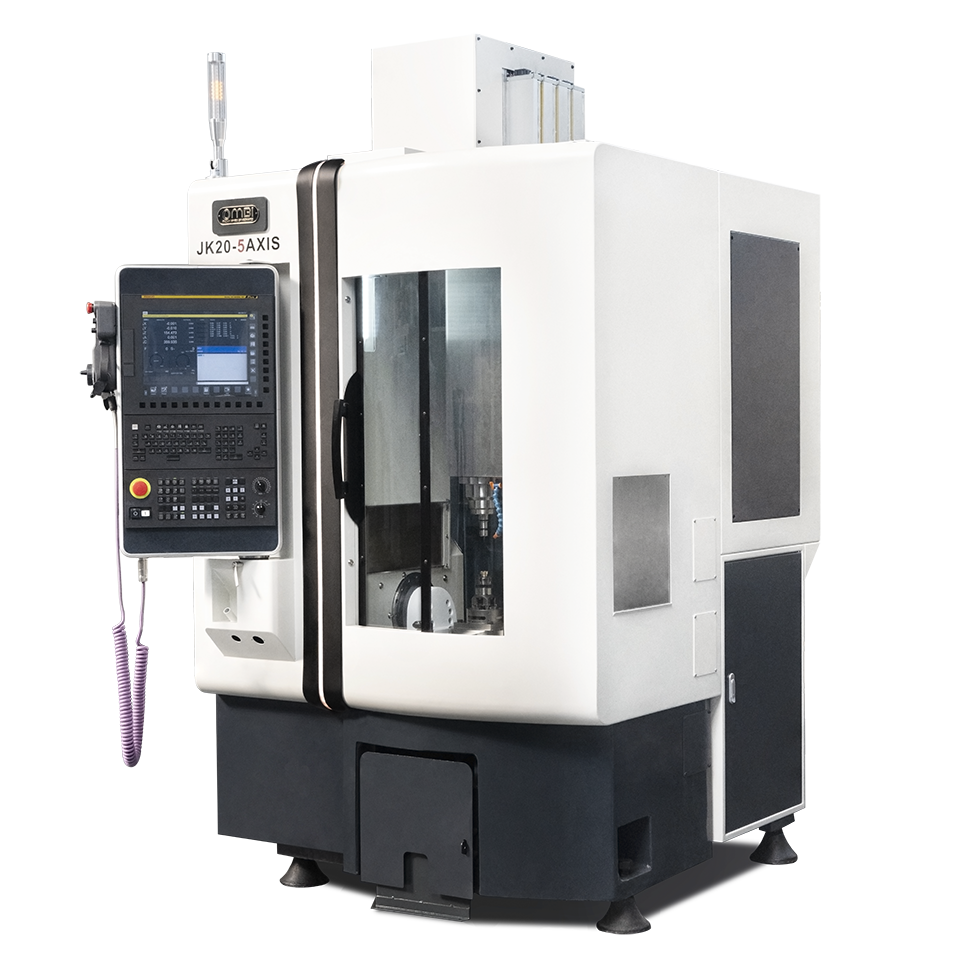

\JK-20

JK-20 Extremely compact 5-axis machining center for high-speed precision

THE STRUCTURE

The structure, made entirely of stabilized cast iron, allows the machine to maintain mechanical precision over time, minimizing deformation caused by temperature variations.

THE KINEMATIKS

The kinematics have been designed to prevent any kind of failure. In this way the machine obtains high results of repositioning in space.

FEM ANALYSIS

With the support of a careful FEM analysis it is possible to combine perfectly highly dynamic performance with guaranteed repeatability of axis positioning.

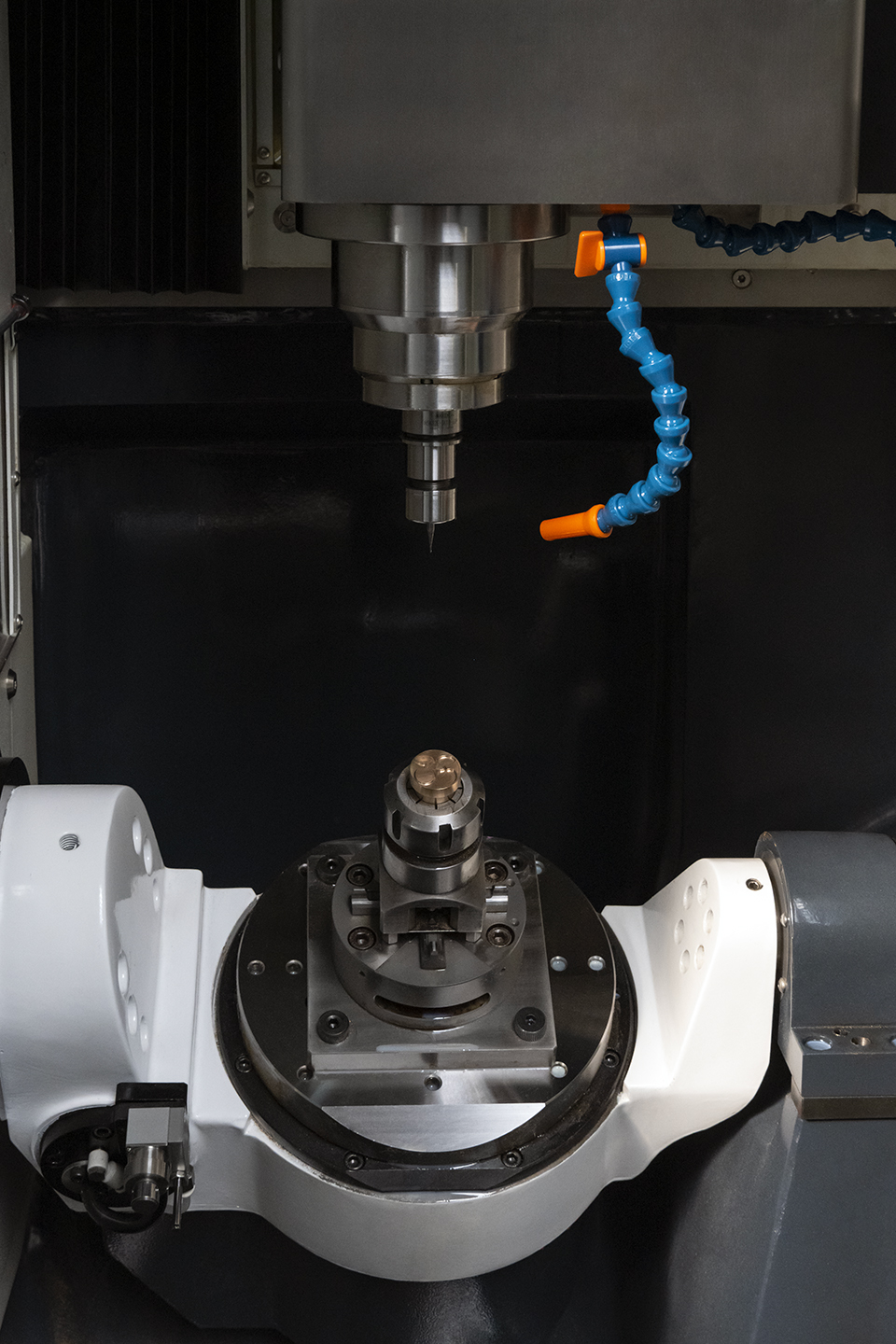

RELIABILITY

The rotating axes C and A with DIRECT DRIVE MOTOR technology guarantee exceptional dynamics combined with very high reliability and precision over time, eliminating the risk of backlash between the worm screw and the crown wheel.

ELECTROSPIDLE

High speed electrospindle for micro machining of very high precision.

THERMAL STABILITY

The sensors control the temperature and the circulation of the liquid cooling positioned in the areas most subject to thermal deformation, allow you to prevent any errors by significantly decreasing the non qualitative compliance in the workshop..

Description JK-20

JK-20 Extremely compact 5-axis machining center for high-speed precision machining conceived for the production needs of the goldsmith, jewelry, watchmaking, fashion accessories and electrode manufacturing sectors.

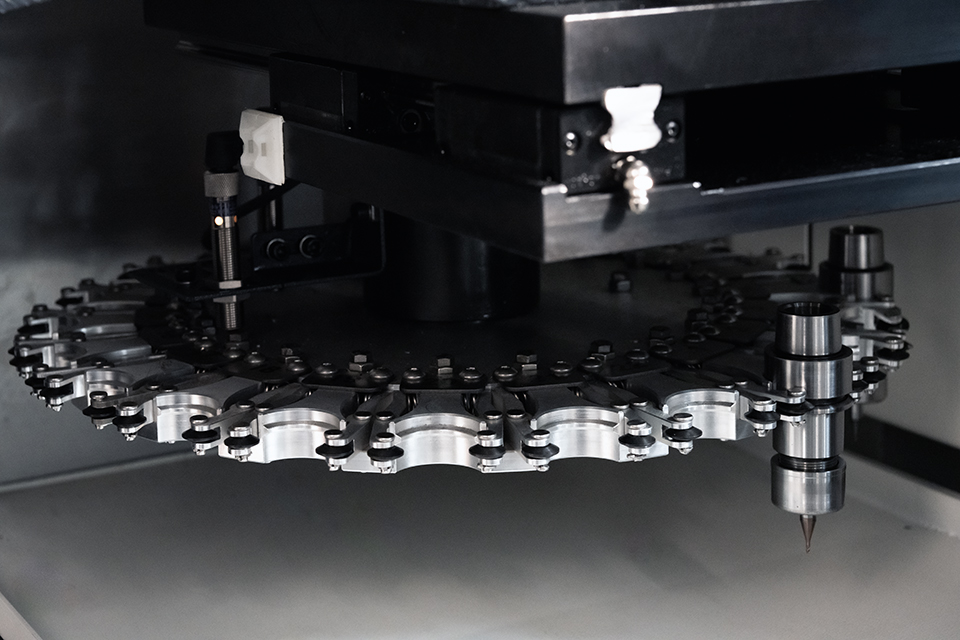

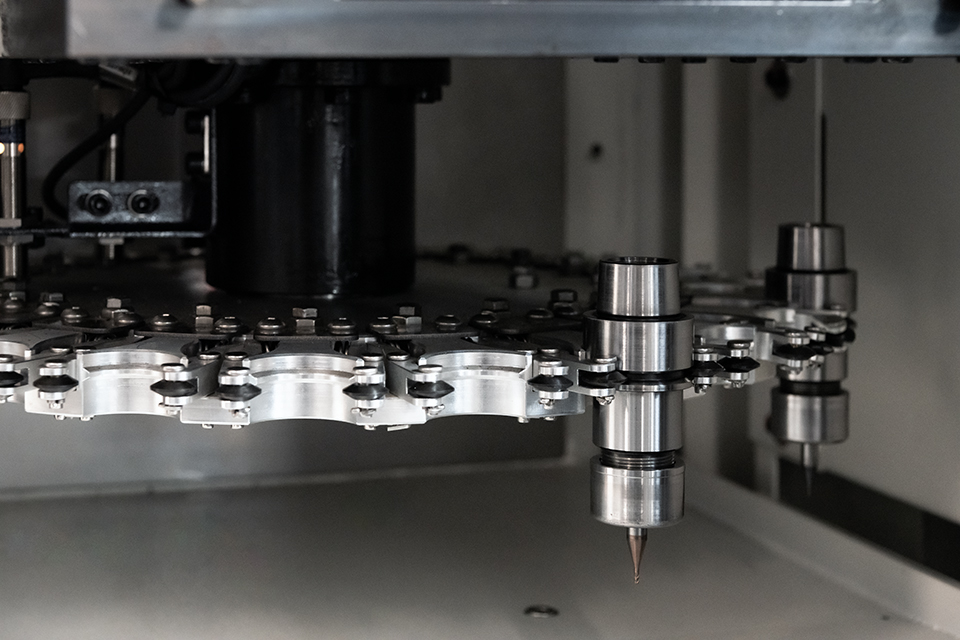

The 22-position automatic tool changer with integrity control and the extremely rigid cast iron basement allow the use of micro milling cutters on very high precision machining and excellent surface finishes.

The machine in its standard configuration is predisposed for the use of an automatic workpiece loading/unloading device which allows production even unhanned 24H a day.

The morphology of the machine and the exceptional accessibility allow the recovery of chips of precious materials after machining in an easy and optimal way.

Technical data

Races

Assi X,Y,Z/Axis X,Y,Z 250/250/250 mm

Asse A/A Axis 125°

Asse C/C Axis 360°

Table size

200 mm°

Max table load

30 Kg

Workpiece size

(Ø / h) 200 / 200

Max. spindle speed

giri/min 36.000

Couple

Nm 2,6

Power

kW 4,35

Tool attachment type

HSKE32

Feeding speed

X,Y,Z mm/min 15.000

Asse A/A Axis rpm 50

Asse C/C Axis rpm 100

Tools warehouse

n° 22 (HSKE32)

Max tool length

mm 125

Max tool diam

mm 10

Max tool weight

kg 1

Rolling guides (X/Y/Z) mm

24/28/24

Ball Screws (X/Y/Z)

mm 25/25/25

3 axis positional accuracy

0,004

Position accuracy AC axe

0,002°

Machine weight approx

Kg 2.000

Machine output

380V 20A Three-phase

Machine size

1280 x 1735 x 2010

Photogallery